Wood is the only major building material that is renewable—a reason why Canada’s forest base is still abundant after 150 years of harvesting. For every Western Red Cedar that’s harvested, at least 3 are planted. Lumber producers have been replacing harvested trees so diligently over the last few decades that North American forests have actually grown by 20% since 1970.

Wood is durable, allowing it to last for a very long time. Churches in Norway and temples in Japan have lasted over a thousand years. In North America, there are many examples of historic wood buildings from the 16th century that are still standing. Even the foundation of the Empire State Building rests on wood piles. In fact, wood not only lasts, but there are many examples of new buildings that have used wood reclaimed from decommissioned buildings. This is the ultimate in reducing the consumption of materials, as there are very few building materials that are reused in this way when a building decommissioned.

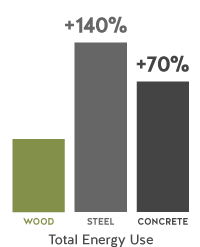

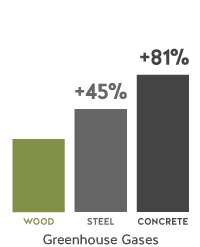

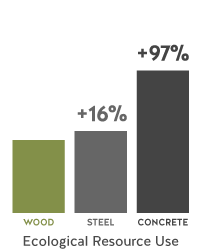

Wood products require much less energy to produce than concrete or steel – that’s according to an independent study that compared how much energy is needed to obtain, manufacture, transport and install building materials for identical wood frame, steel frame and concrete houses. These findings prove, once and for all, that wood is environmentally superior to alternative materials. And on top of that, wood has naturally occurring thermal properties. It conducts heat and insulates better than steel and concrete, so it saves even more energy (not to mention money) when it comes to heating and cooling homes.

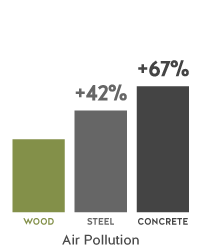

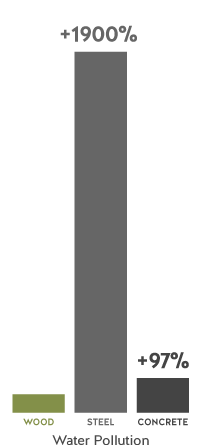

Cedar, along with other wood products, has the lowest impact of all building materials on air and water quality. For starters, the manufacturing of wood products produces far fewer toxins and greenhouse gases than the leading man-made materials. But it gets better than that; the regeneration of forests after harvest creates new trees, which take in carbon dioxide and release oxygen as they grow. That’s great news for the environment.

Man-made materials—including brick, cement and composite products—don’t break down like wood does once it’s discarded.

Western Red Cedar is green by nature, but certification is a bonus for consumers looking for an added assurance. More than 85 percent of timberland in British Columbia, Canada—where most western red cedar comes from—is certified by internationally recognized, independent forest certification agencies.

See these 3rd party links for facts on British Columbia’s forest practices:

naturally:wood

forestryforthefuture.ca

See how wood like Western Red Cedar stacks up against other building materials.

|  |  |

|  |  |

Minimizing external pollution and environmental damage.

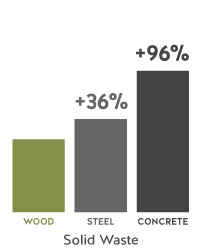

In evaluating the environmental impact of building design, the impact on the quality of air, water and soil must be taken into consideration. This includes not only minimizing waste products from the building, such as wastewater, solid wastes and chemicals, but also minimizing the pollution caused by the manufacture of the materials used in the building.

It is difficult, however, for designers to determine whether the materials they choose cause air or water pollution during their extraction, manufacture and transportation to the site as these occur away from the project. Designers may be aware that concrete manufacture creates CO2 emissions and that steel manufacture results in toxic chemicals being released into the water, but are not aware of a means to evaluate these effects. Life cycle analysis is an emerging science that evaluates and allows designers to compare the effect that materials have on the environment over their lifetime.

In Canada, the ATHENA™ Sustainable Materials Institute has developed databases and a computer program to evaluate the environmental impacts of whole buildings and building assemblies. In the US, the federal government has funded the first phase of a project, led by the ATHENA™ Sustainable Materials Institute, to develop a life-cyle inventory for a range of materials including building materials and products. The second phase of the project is now getting underway.

ATHENA™’s life-cycle research proved what designers knew intuitively, and what has been demonstrated in comparable work in Europe: when it comes to minimizing external pollution of air, water or soil, wood far surpasses other materials. The research demonstrated that using wood results in:

- lower greenhouse gas emissions than steel or concrete

- lower air pollution than steel or concrete

- lower water pollution than steel or concrete

- lower solid waste by-products than steel or concrete

The next section, A Life Cycle Approach to Building Design, provides further explanation about life cycle analysis and how wood building products have the lowest environmental impact when compared to other major building materials.

What is forest product certification.

More than 85 percent of timberland in BC, which is the primary source for western red cedar, is certified by internationally recognized, independent, third-party forest certification agencies.

The point of independent, third-party evaluations is to protect environmental values such as biodiversity, soil and water quality. Here’s how they work:

Evaluation

Forest companies operating in BC must meet or exceed the high forest management standards demanded by government. In addition, they also have a high level of third-party certification, which gives customers added assurance that they are practicing responsible and sustainable forest management.

Environment

The forests are assessed according to rigorous, measurable and scientific criteria that include ensuring protection of biodiversity and preserving soil and water quality.

Label and Chain of Custody

Forest products can include a label indicating they have been approved as environmentally-friendly and a chain-of-custody system, which tracks a wood product from a tree in the forest through all the steps of processing and production until it reaches the consumer.

Environmental product declarations.

Here are the Environmental Product Declarations for the following Western Red Cedar products:

Typical Western Red Cedar Decking – Valid till 2030